-

COMPANY

WHY CHOOSE  LUC&BEL:

LUC&BEL:

More than thirty years of EXPERIENCE.

High quality RESEARCH.

INNOVATIVE and RELIABLE production technology.

A unique range of products from SINGLE COMPONENTS to PRE-ASSEMBLED ITEMS.

High technology skills from the

DESIGN and MAKING of the MOLDS to the DESIGN and REALIZATION of

- AUTOMATIC ASSEMBLY MACHINES

- AUTOMATED WORKING AREAS.

NEWS

NEWS

Luc & Bel S.r.l. built and opened a new clean room, in order to increase its production areas from 1.200 square meters to 1.750 square meters in ISO Class 8 (Rif.: EN ISO 14644- 1) dedicated to new working areas with the automatic machines stations.

At the same time, a new warehouse of 600 square meters for the storage of the semi-finished products was built and opened, reaching a total plant size of 5.000 square meters.

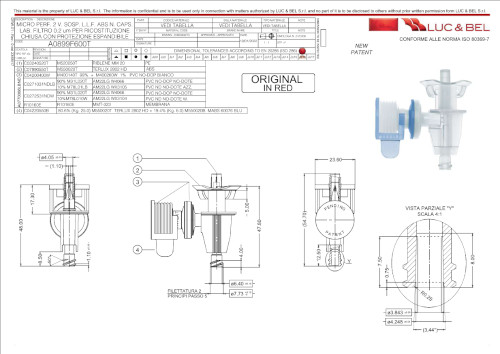

It has already been active in the adjustment process on the luer cones of its components to be in compliance with ISO 80369-7 standard, with the measuring device 3D CNC that use an optical measuring system with a probe.

NEWS

NEWS

Luc & Bel S.r.l. is now fully integrated and is generating great synergies for the group with sister companies Modenplast and Kabo.

The companies are working hard to provide comprehensive solutions in the field of fluid management for medicine; from polymer compounds to tubes, connectors, filters and other molded products. With expertise in moulds design, moulding and machines building for the assembly of medical components, Luc & Bel adds considerable value to existing expertise in polymer compounding and extrusion.

Thanks to the cooperation of Luc & Bel, Modenplast and Kabo, ARTEREX is now a "one stop" supply shop for the polymer-based medical needs and know-how.